What are fixing devices?

According to UL 62275; CSA C22.2 No. 62275 and NMX-J-623-ANCE, they are defined as components specifically designed to secure the cable tie to a mounting surface. These can be separately supplied devices or manufactured integrally with the cable tie. Fixing devices are available in a variety of constructions such as screw mount, adhesive mount and push mount ( self-fastening ) .

The principal measure of performance for a fixing device is its mechanical strength, as defined by specified tests. Testing for mechanical strength will vary based on the fixing device construction, and whether the fixing device is separately supplied or integral with the cable tie.

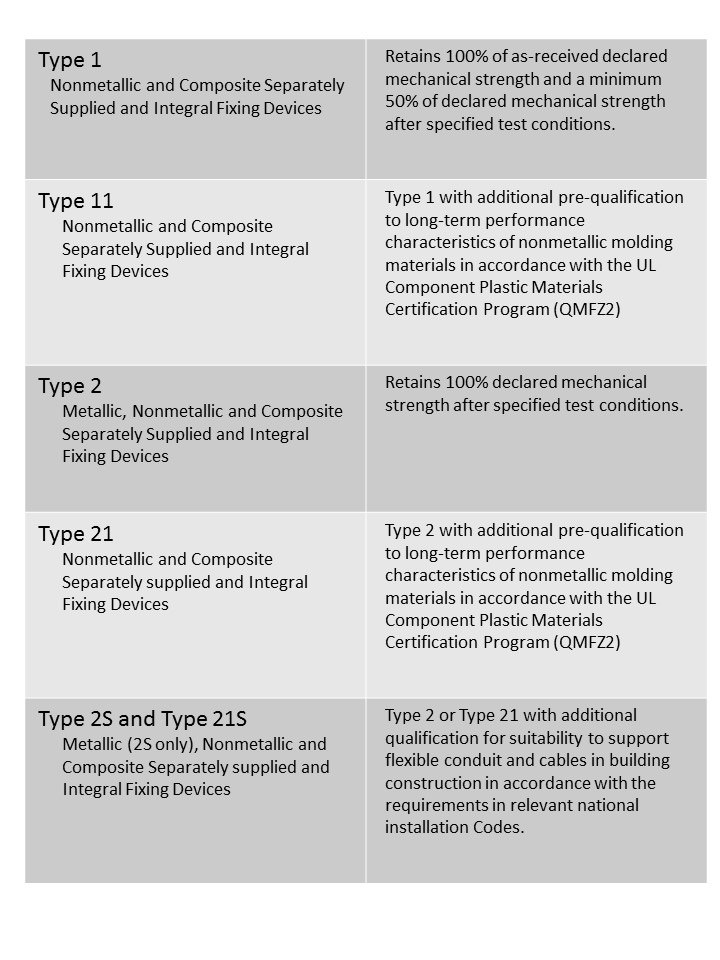

Like cable ties, fixing devices are identified by “Type” classifications and standard performance ratings declared by the manufacturer and confirmed by the tests in the standard. Integral products are marked with the Type classification of the cable tie as follows:

Marking of fixing devices

Separately supplied fixing devices are marked with their mechanical strength, while integral devices are marked with both the mechanical strength of the fixing device and the loop tensile strength of the cable tie. If both are the same, a single value is marked. If they differ, both are marked.

Testing of fixing devices

Fixing devices are required to be tested the same as cable ties, both as-received and after specified conditioning, except that fixing devices are evaluated for their mechanical strength. The objective of mechanical testing is to determine if the fixing element such as a saddle or bridge is capable of retaining the cable tie after a specified tensile load.

For more information about Type classifications, ratings and industry standards, see NEMA Cable Tie “Type” Classifications guide.

DISCLAIMER

The standards or guidelines presented in a NEMA standards publication are considered technically sound at the time they are approved for publication. They are not a substitute for a product seller’s or user’s own judgment with respect to the particular product referenced in the standard or guideline, and NEMA does not undertake to guarantee the performance of any individual manufacturer’s products by virtue of this standard or guide. Thus, NEMA expressly disclaims any responsibility for damages arising from the use, application, or reliance by others on the information contained in these standards or guidelines.

RFQ (

RFQ (